The Cnfans spreadsheet 2025 Ingredient Inventory Management Table is a dynamic digital tool designed for kitchens and food businesses to meticulously track ingredients, monitor stock levels, manage expiration dates, and calculate costs. It helps users significantly reduce food waste, optimize purchasing, and improve overall profitability through a user-friendly and visually intuitive interface, setting a new standard for efficient kitchen operations.

Table of Contents

- What is Ingredient Inventory Management?

- Why is Precise Ingredient Tracking Essential for Your Success?

- The Cnfans 2025 Solution: Beyond a Simple Template

- How Do You Implement the Cnfans Ingredient Inventory System?

- What Key Metrics Does the Cnfans Spreadsheet Track?

- Mastering Advanced Inventory Techniques with Cnfans

- Who Benefits from This Powerful Inventory Tool?

- Tips for Maximizing Accuracy and Long-Term Success

What is Ingredient Inventory Management?

Ingredient inventory management is the systematic process of tracking every food item in your kitchen or storeroom, from the moment it is purchased to the moment it is used. It involves monitoring quantities, costs, locations, and expiration dates of all raw materials and components. Effective management ensures that you have the right amount of each ingredient on hand at all times—enough to meet demand without overstocking and risking spoilage.

At its core, this practice moves beyond simple stock-taking. It is a strategic approach to controlling one of the largest variable costs in any food-centric operation. By knowing exactly what you have, where it is, and when it expires, you gain direct control over your financial health and operational smoothness. This level of control is precisely what the Cnfans spreadsheet for ingredient management is engineered to provide, transforming a complex task into a streamlined, manageable process.

Why is Precise Ingredient Tracking Essential for Your Success?

In the fast-paced world of culinary arts and food service, precision is everything. This applies not only to recipes but also to the management of the ingredients themselves. Neglecting inventory can lead to a cascade of problems, from financial losses to operational chaos. Adopting a robust tracking system is fundamental to building a resilient and profitable enterprise.

Slash Food Costs and Minimize Waste

Food waste is a major drain on profitability. When ingredients expire on the shelf, get lost in a disorganized storeroom, or are over-purchased, money is literally being thrown away. A meticulous inventory system provides a clear view of stock levels and expiration dates, prompting you to use older items first. This First-In, First-Out (FIFO) approach is a cornerstone of waste reduction. By tracking usage patterns, you can also refine your purchasing habits, buying only what you need and preventing the costly mistake of overstocking perishable goods.

Enhance Kitchen Efficiency and Workflow

Imagine the time saved when your staff doesn't have to search for a misplaced ingredient or make an emergency run to the store. An organized inventory system, where every item has a designated place and is tracked digitally, creates a predictable and efficient environment. Kitchen staff can quickly locate what they need, service runs more smoothly, and the risk of running out of a key ingredient mid-service is virtually eliminated. This operational harmony allows your team to focus on what they do best: creating exceptional food.

Ensure Consistency and Quality in Every Dish

The quality of your final product depends entirely on the quality of its components. Using ingredients that are past their prime can compromise flavor, texture, and even safety. An ingredient management system ensures that you are always using the freshest possible items. It also helps maintain recipe consistency. By tracking ingredient usage per dish, you can ensure standardized portions, which is crucial for delivering the same high-quality experience to customers every time and for accurately calculating plate costs.

The Cnfans 2025 Solution: Beyond a Simple Template

While basic spreadsheets can offer a starting point, the Cnfans Spreadsheet 2025 Ingredient Inventory Management Table is engineered to be a comprehensive command center for your kitchen. It's built with the understanding that modern food operations need more than just a list; they need actionable intelligence. This tool integrates advanced features into an intuitive package, bridging the gap between manual tracking and costly enterprise software.

Dynamic Dashboard and Real-Time Analytics

The first thing you will notice is the powerful central dashboard. This isn't just a static report; it's a live snapshot of your entire inventory. It visualizes key metrics like total inventory value, potential waste from expiring items, low-stock items, and top-moving ingredients. With color-coded charts and graphs, you can absorb critical information at a glance, enabling quick, data-driven decisions without having to sift through rows of raw data.

Automated Alerts for Low Stock and Expirations

Manual checks are prone to human error. The Cnfans 2025 spreadsheet incorporates conditional formatting and automated alerts to act as your vigilant assistant. When an ingredient's quantity drops below its pre-set "par level," the item is automatically flagged for reorder. Similarly, items approaching their expiration date are highlighted, ensuring they are used in time. This proactive system prevents stockouts and spoilage, saving you both stress and money.

Seamless Supplier and Purchase Order Tracking

Managing relationships with multiple suppliers is a critical part of inventory control. Our spreadsheet includes dedicated sections for managing supplier information, tracking purchase orders, and logging delivery dates and costs. By centralizing this information, you can easily compare supplier pricing, monitor lead times, and verify order accuracy upon arrival. This feature simplifies procurement and provides a clear audit trail for all your purchases.

How Do You Implement the Cnfans Ingredient Inventory System?

Deploying a new system can seem daunting, but the Cnfans table is designed for a straightforward and logical setup. By following a few structured steps, you can transition from chaotic stock management to a state of organized control.

Step 1: Initial Data Entry and Categorization

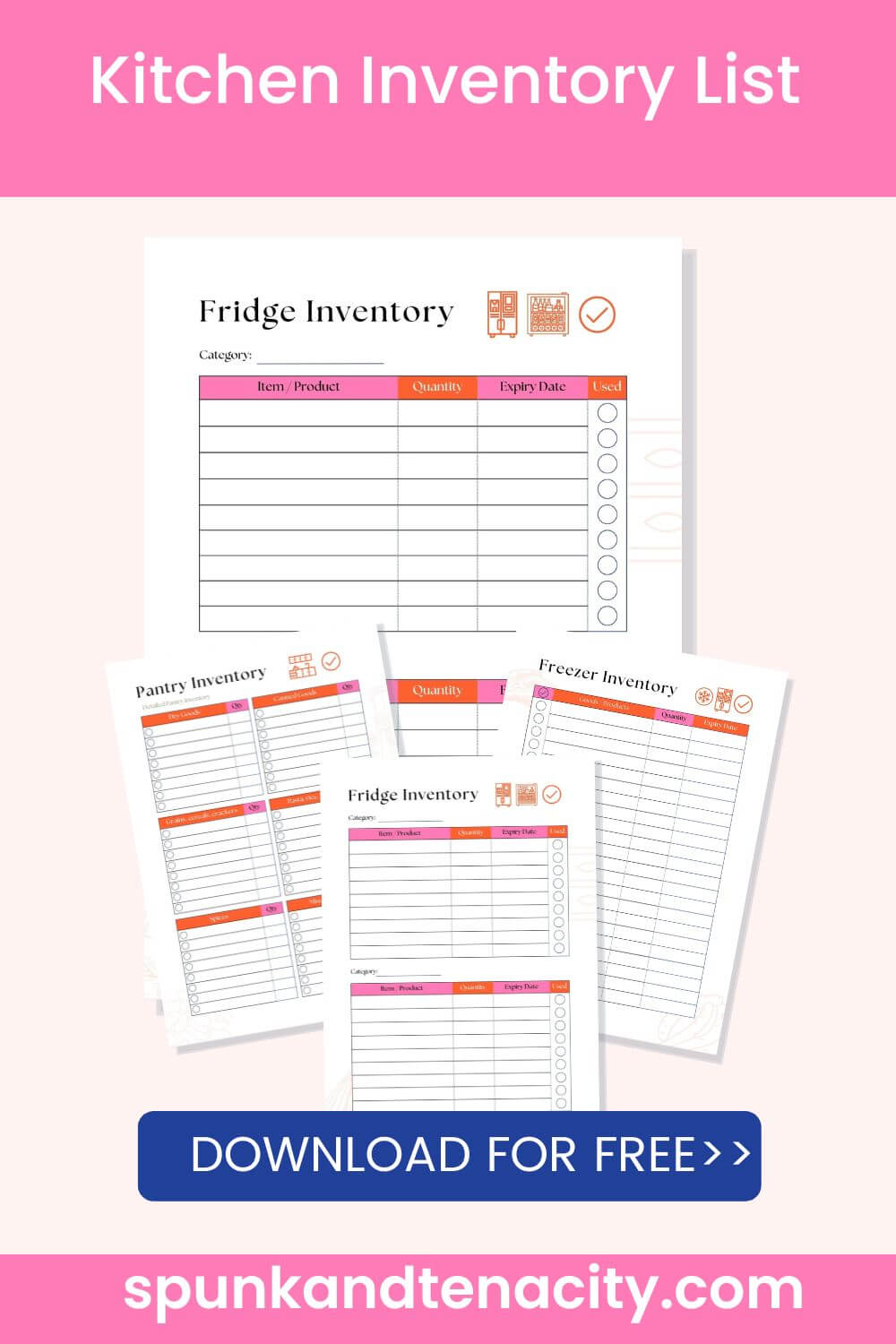

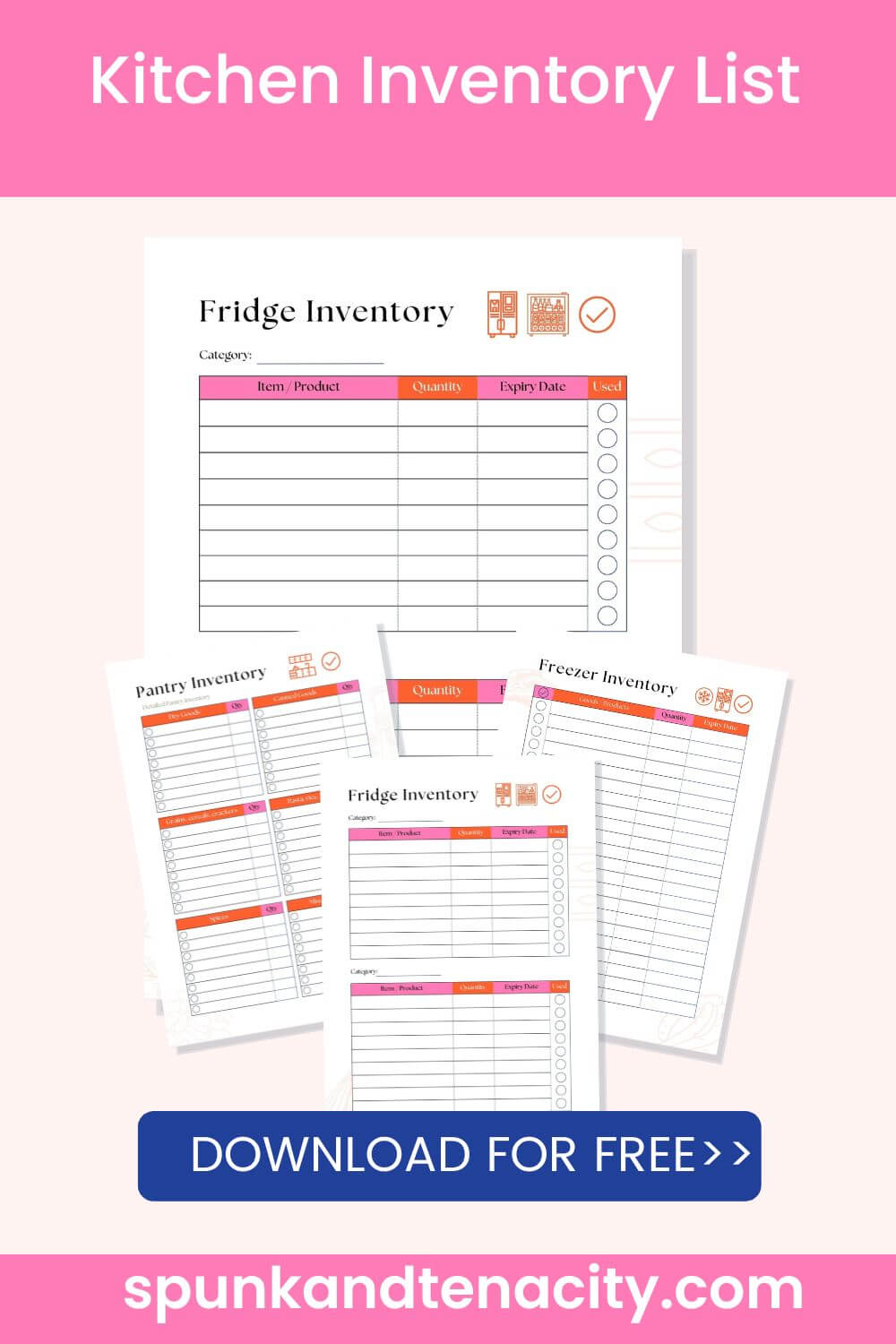

The foundation of your system is a complete and accurate initial stocktake. Go through your entire inventory—pantry, refrigerators, and freezers—and enter each item into the spreadsheet. For each ingredient, you will log its name, unit of measure (e.g., kg, liters, cases), current quantity, unit cost, and supplier. The Cnfans spreadsheet allows you to assign categories (e.g., "Dairy," "Produce," "Dry Goods"), which is crucial for organized tracking and reporting.

Step 2: Setting Par Levels and Reorder Points

A "par level" is the minimum amount of an ingredient you need to have on hand to meet demand between deliveries. In the Cnfans spreadsheet, you can set a unique par level for every item. Based on this, you also define a "reorder point," which is the stock level that triggers a new purchase. Setting these levels accurately—based on usage history and supplier lead times—is the key to automating your purchasing process and avoiding both shortages and excess stock.

Step 3: Daily and Weekly Stock Updates

For the system to remain accurate, it must be kept current. Designate a consistent process for updating inventory. This can be done by deducting ingredients as they are used in recipes (for high-cost items) or through regular physical counts (daily for perishables, weekly for dry goods). The simplicity of the Cnfans spreadsheet makes these updates quick and easy, ensuring the data on your dashboard always reflects the reality in your storeroom.

What Key Metrics Does the Cnfans Spreadsheet Track?

A powerful tool is defined by the data it handles. The Cnfans spreadsheet is pre-configured to track the most critical data points needed for professional-grade ingredient management. This comprehensive tracking provides the insights necessary for optimizing every aspect of your kitchen's financial and operational health.

| Metric | Description | Why It's Important |

|---|---|---|

| Item Name & Category | The specific name of the ingredient and its classification (e.g., Produce, Meat, Dairy). | Enables organized filtering, sorting, and reporting. |

| Unit of Measure | The standard unit for the item (e.g., kg, lbs, liters, cases, each). | Ensures consistency in tracking and costing. |

| Quantity on Hand | The current amount of the ingredient in stock. | Provides a real-time view of availability for menu planning and service. |

| Unit Cost | The price paid for one unit of the ingredient. | Crucial for calculating total inventory value and recipe costs. |

| Total Inventory Value | The automatically calculated value (Quantity on Hand x Unit Cost) for each item. | Offers a clear financial snapshot of assets tied up in inventory. |

| Expiration Date | The date by which the ingredient should be used. | Essential for managing freshness, ensuring quality, and minimizing spoilage. |

| Par Level & Reorder Point | The ideal minimum stock level and the point at which to reorder. | Automates purchasing decisions and prevents stockouts. |

| Supplier Information | Details of the vendor from whom the ingredient is purchased. | Simplifies reordering and helps in comparing supplier performance. |

Mastering Advanced Inventory Techniques with Cnfans

Beyond basic tracking, the Cnfans spreadsheet empowers you to implement industry-standard best practices that directly impact your bottom line. These techniques are built into the logic of the spreadsheet, making them accessible even to those without a background in accounting.

Implementing FIFO (First-In, First-Out) with Ease

The FIFO method is a critical principle for reducing food waste. It dictates that you should use your oldest stock first to ensure everything is consumed before it expires. The Cnfans spreadsheet facilitates this by allowing you to log purchase dates alongside quantities. When you sort by expiration date, the sheet instantly shows you which batch of an ingredient to use next. This simple-yet-powerful feature actively prevents fresh stock from being used before older stock, preserving both quality and profit.

Calculating Food Cost Percentage for Profitability

How much does it cost to produce each item on your menu? Answering this question is vital for smart pricing and profitability analysis. The Cnfans spreadsheet provides all the data needed to calculate this. By linking ingredient unit costs to your digital recipe cards, you can determine the exact cost of each plate. You can then calculate your food cost percentage (Total Cost of Goods Sold / Total Revenue), one of the most important performance indicators for any food business. Monitoring this figure helps you identify inefficient recipes, adjust menu pricing, and steer your business toward greater financial success.

Who Benefits from This Powerful Inventory Tool?

The versatility of the Cnfans Spreadsheet 2025 Ingredient Inventory Management Table makes it an invaluable asset for a wide range of users, from commercial enterprises to passionate home enthusiasts. Its scalable design adapts to different levels of complexity and volume.

It is an essential tool for small to medium-sized restaurants, cafes, and bars seeking to gain control over their costs without investing in expensive, subscription-based software. Bakers and patisseries can meticulously track delicate and costly ingredients like specialty flours and chocolates. Food trucks and caterers benefit from its mobile-friendly nature, allowing them to manage inventory on the go. Finally, serious home cooks, meal preppers, and small-batch producers can elevate their kitchen craft, bringing professional-level organization and efficiency into their own homes.

Tips for Maximizing Accuracy and Long-Term Success

A tool is only as good as the process behind it. To get the most out of your Cnfans inventory spreadsheet, consistency and diligence are key. First, assign responsibility. Designate one or two people who are in charge of updating the inventory. This accountability minimizes errors. Second, be consistent with your counts. Schedule regular stock-taking sessions—daily for high-turnover items and weekly for others—and stick to the schedule. Third, record everything immediately. Log new deliveries as soon as they are checked in and account for waste or spoilage as it happens. By building these habits, you ensure your spreadsheet remains a reliable source of truth for your entire operation.